PCB edge plating plays an indispensable role in ensuring the reliability of PCBS and extending their service life

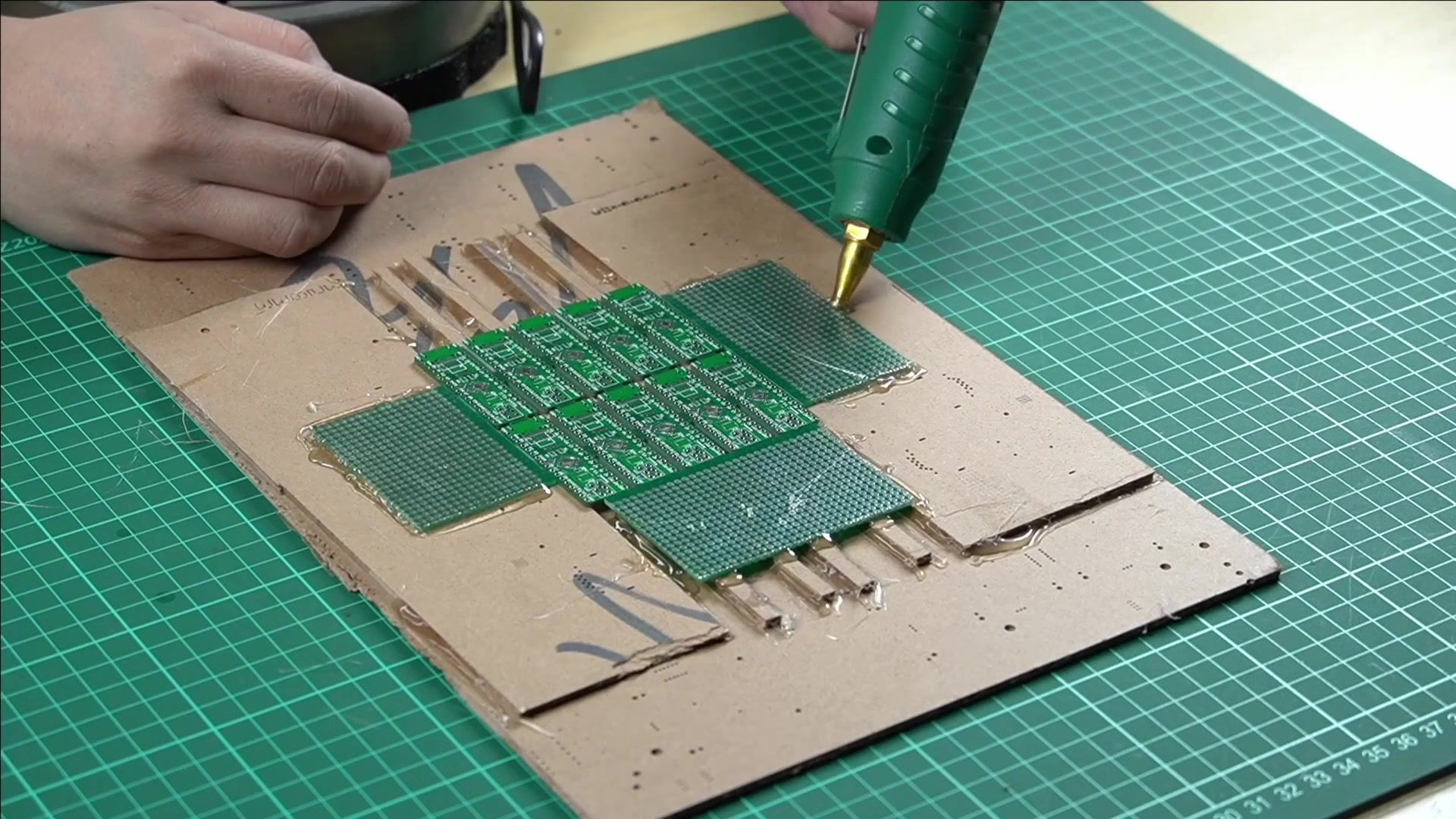

The process of PCB edge plating

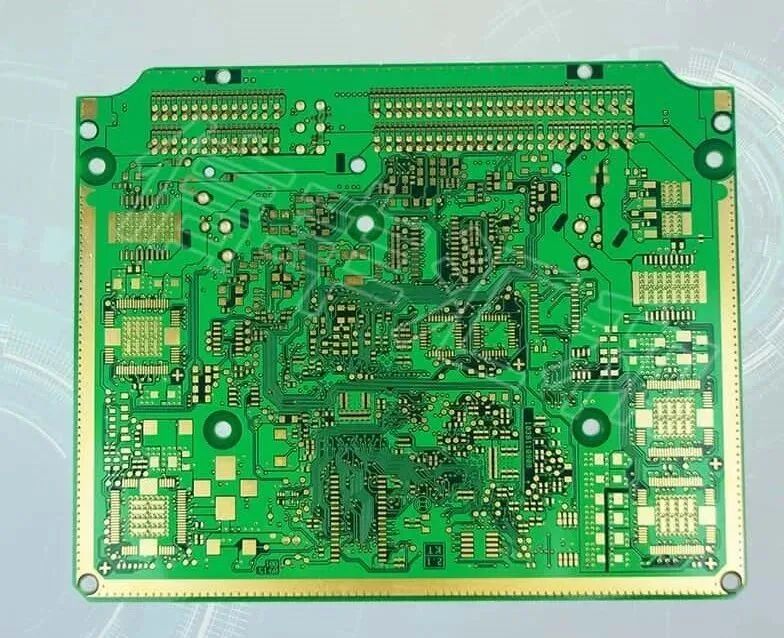

PCB edge plating, also known as edge plating, edge coating or edge protection, is a special processing technology in the PCB production process. Specifically, it involves covering the outer edge of the PCB, that is, the non-wiring area, with a thin layer of metal (commonly tin, nickel, gold, etc.) or insulating material through chemical deposition, electroplating or other methods.

This additional layer of covering is not limited to the edge of the plate; sometimes it extends to the edge of the borehole to enhance its structural integrity and electrical performance.

The role of the PCB edge plating process

1. Prevention of corrosion and oxidation: During the use of PCBS, the edges are prone to corrosion or oxidation due to environmental factors such as changes in humidity and temperature, especially for the parts not fully covered by copper foil. Edge wrapping can form a barrier, effectively isolating the external environment, reducing the risk of corrosion and extending the service life of the PCB.

2. Enhance mechanical strength: Edge coating can significantly improve the impact resistance and wear resistance of PCB edges. Especially in application scenarios involving frequent plugging and unplugging, vibration or bending, edge wrapping can effectively prevent the board edges from cracking or copper foil from peeling off, maintaining the structural stability of the circuit board.

3. Improve solderability and connectivity: For PCBS that require edge connections or plug-in installations, edge banding can provide a flatter, more uniform and easier-to-solder surface. Especially when tin-plated or gold-plated, it can significantly enhance the quality and reliability of soldering.

4. Electromagnetic shielding and signal Integrity: In high-frequency circuit design, edge wrapping can also play a certain role in electromagnetic shielding, reducing external interference and protecting sensitive signals from being affected. This is particularly crucial for enhancing the performance of the entire electronic system.

5. Aesthetics and Identification: Although this is not the main function, in some cases, the edge of a specific color or material can also serve as a visual identifier for the product or a mark to distinguish different versions, enhancing the product's recognition.